Fiberglass needle punced non woven coth felt

Informations de base

Modèle: AOBO-Fiberglass felt

Description du produit

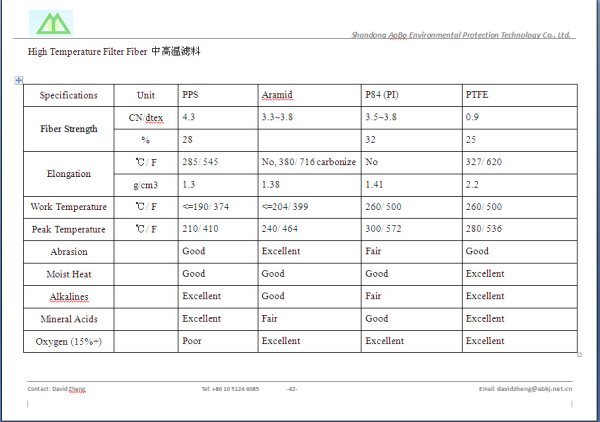

FMS is a good high temperature resistance filter fabrics, this fabrics mainly made by 5.5 micron diameter glass fiber blend with P84 (polyimide), aramid(Nomex), PPS (ryton) fiber, with the three dimensional cellular structure, low air resistance, especial blend with P84 which with leaf style fiber, can increase the filter surface (80%), so easy to collect the dust, increase the fiber cohesion, can accept the high wind speed (50% higher about 1~1.4m/min), and also with the properties of abrasion resistance. This kind of fabrics widely used in metallurgical plant, chemical plant, coal fired boiler, incinerator, cement plant for dust collector or smoke filtration in high temperature circumstance.

Application

Iron and steel industry

Colored metallurgy

Chemical industry

Coal black

Building material

Electric power Industry.

Specification

Composition |

P84/Glass fiber/PTFE |

|

Weight (g/m2) |

800 |

|

Thickness (mm) |

2.5 |

|

Air permeability (L/m2/s) |

8-15 |

|

Tensile strength (N/5X20cm) |

Warp |

3000 |

Weft |

3100 |

|

Tensile elongation (%) |

Warp |

<10 |

Weft |

<15 |

|

Broken strength (Mpa/min) |

3.85 |

|

Working temperature(°C) |

250 |

|

Short time working temperature(°C) |

270 |

|

Anti-acid |

Excellent |

|

Anti-alkali |

Excellent |

|

Anti-abrasion |

Excellent |

|

The stability of water solution |

Medial |

|

Finishing treatment |

PTFE treatment |

|

Application Common industry applications for fabric filter

Industry |

Sources |

Steel |

Electric arc furnaces Sintering plants Boilers |

Foundries |

Cupolas |

Nonferrous metals |

Lead furnaces Copper smelting furnaces Zinc furnaces |

Grain handling |

Cleaning operations Grinding mills Mixers and blenders Material transfer |

Mineral processing |

Crushers Grinding mills Screening operations Air classifiers Dryers Kilns Calciner |

Cement |

Raw mills Kilns Finish mills |

Asphalt concrete |

Drum mixers |

Glass |

Melting furnaces |

Chemical |

Dryers Grinding mills |

Power plants |

Coal-fired boilers |

Waste disposal |

Incinerators |

Felt Filber & Process:

Packaging & Shipping

Our Services

1.Excellent Quality

FIRST-CLASS PRODUCTION EQUIPMENT

Our factory adopted professional filter media production line, filter felt production line and treatment production line.

PERFECT EXPERIMENTAL EQUIPMENT

Our advanced equipment allows us to make all parameters testing of our fabric, such as weight, thickness, air permeability, tensile strength, etc.

PROFESSIONAL ENGINEERS

To ensure our products quality, our professional engineers have to do all tests including: Chemical index test, strength test, abrasion test, fiber analysis, air permeability, water & oil repellent test, fine dust test, single fiber strength test, acid & alkali test and geotextile fabric test.

SKILLED AND RESPONSIBLE WORKERS

With very good operating skills in productions, our workers are highly responsible for products.

2.Good Price

Good production management system and efficient production help us save cost.

Good price can be given not at the expense of quality.

3.Perfect Service

Shandong Aobo provides solutions to its customers by supplying high quality products with strong technical support.

PRE-SALE SERVICE

Detailed, professional and complete analysis can help customers with best possible understandings of their applications and requirements. Then best-use technical solutions are provided.

SALE SERVICE

With excellent language skills, our sales people can communicate well with customers from all of the worlds.

With many years experiences of import and export, our sales people are very familiar with international trade flow. These can help customers to save cost and avoid the risk.

With high responsibility, our sales people make your prompt response anytime and help you follow up the production, packing and delivery time.

AFTER SALE SERVICE

Provide customers with technical supervision for filter bag installation.

Provide customers with regular laboratory tests to monitor system and filter bag performance.

If there is any question please kindly let me know, thank you.

Company Information

FAQ

Groupes de Produits : Se sentait

Premium Related Products